Find your language

Maintenance Solutions for Corrosion Under Insulation

Maintenance Solutions for Corrosion Under Insulation

What is Corrosion Under Insulation (CUI)?

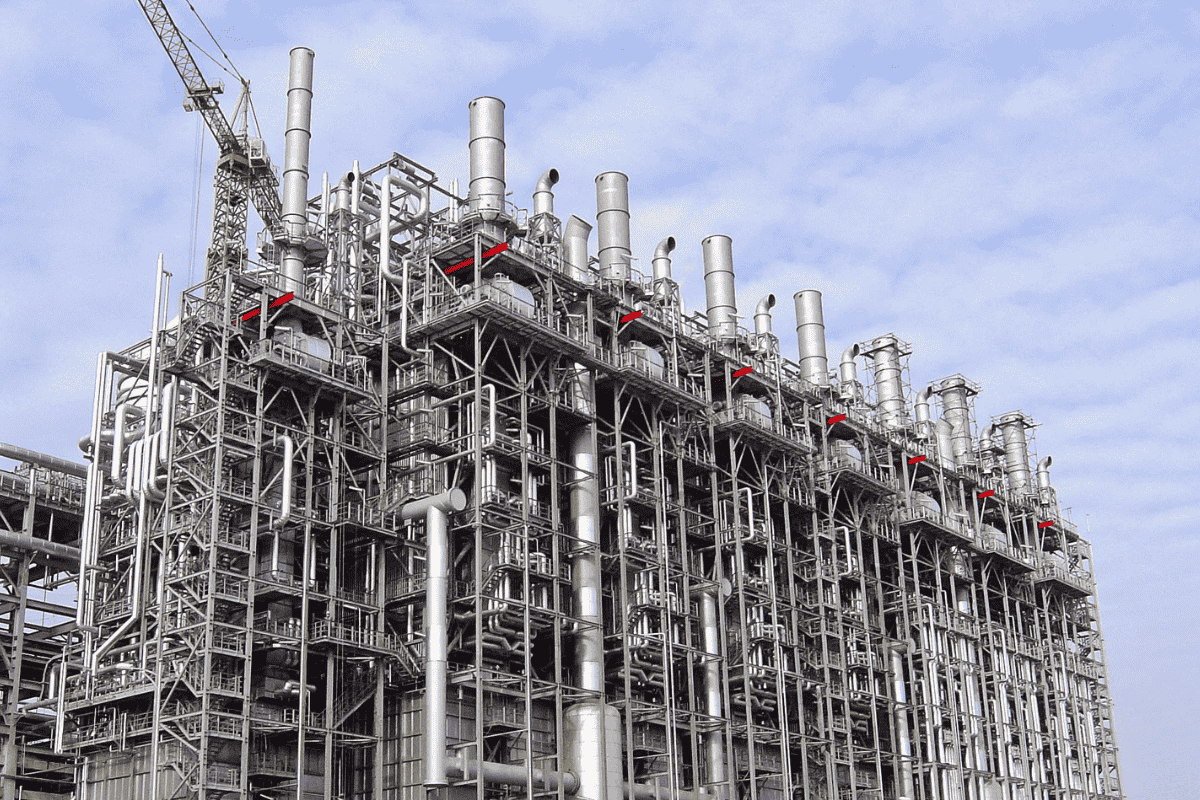

Corrosion Under Insulation (CUI) is one of the most significant maintenance challenges for asset owners.

When moisture becomes trapped beneath insulation, corrosion can develop quickly and often goes undetected. If left untreated, it can:

- Compromise asset safety and integrity

- Cause loss of production due to unexpected shutdown

- Lead to costly repairs and disruption to otherwise planned maintenance

AkzoNobel's CUI & Cyclic Temperature maintenance solutions for downstream oil & gas

High Temperature Maintenance Range

Damage caused by Corrosion Under Insulation (CUI) and temperature cycling within the CUI zone is a major threat to asset integrity in oil and gas facilities.

Our high-temperature maintenance coatings are specifically formulated to deliver long-term resistance and protection against these conditions, helping operators maintain reliable performance and reduce unplanned downtime.

Key Benefits:

- Provide confidence in the safety of your asset

- Reduce downtime through efficient application

- Pre-empt one of the leading causes of asset corrosion

- Efficient application - streamlined application minimising downtime

The High Temperature Maintenance Range includes three specialist coatings, each designed to enhance installation productivity and deliver outstanding in-service performance, helping reduce the overall demands of high temperature maintenance.

Specialist CUI & cyclic temperature coatings

Intertherm® 751CSA

Temperature range: -196°C (-321°F) to 650°C (1202°F)

- Renowned Cold Spray Aluminium (CSA) technology with excellent CUI and thermal cyclic resistance based on Titanium Modified Inorganic Copolymer

- Enhanced resistance to thermal shock during rapid temperature cycling

- Incorporates aluminium pigments for added anticorrosive protection

- Single-coat application at 200µm (8 mils) using standard equipment

- Suitable for application to steel substrates operating at up to 150°C (302°F)

Interbond® 2340UPC

Temperature range: -196°F (-321°F) to 230°C (446°F)

- Reduces the risk of early CUI failure due to aluminium anticorrosive pigments in a phenolic epoxy resin system

- Maximizes productivity with easier application

- Low-temperature cure down to -5°C (23°F) using alkylated amine epoxy technology

- Excellent tolerance to over-application

- Short minimum overcoating intervals

- Suitable for application to steel substrates operating up to 120°C (250°F)

Intertherm® 2205

Temperature range: Up to 230°C (446°F)

- No need for shutdowns - can be applied directly to high-temperature online equipment

- Hot application possible up to 205°C (401°F)

- Excellent adhesion to hand- or power-tool–cleaned steel (St2/SP2)

- Ready to insulate within 10 minutes after application at >100°C (212°F)

- Excellent CUI protection due to added anticorrosive aluminium pigments in phenolic epoxy solution

Intertherm 2205 capabilities video

Why choose a versatile CUI maintenance solution?

Maintenance is a year-round challenge, with coatings exposed to varying application conditions.

Traditional epoxy phenolic coatings for CUI service often struggle because they:

- Do not cure below 10°C (50°F), causing delays in winter months

- Have low tolerance to over-application, common in maintenance work on pitted steel

- Can crack under stress during high temperature service

Our high temperature maintenance coatings are formulated to overcome these issues, delivering greater resilience in CUI and cyclic temperature service environments.

Resources on CUI & cyclic temperature solutions

Intertherm 751CSA resources

- 751CSA Infographic

- 751CSA Factsheet

- Meet the experts

- 751CSA Sales presentation

- History highlights for facility owners

- History highlights for applicators

Intertherm 2205 resources

Interbond 2340UPC resources

Contact us

We are here to help

Our global team of technical and sales experts are available to provide you with the help and support that you need.