Find your language

AkzoNobel's Passive Fire Protection maintenance solutions for downstream oil & gas

Does your existing passive fire protection work?

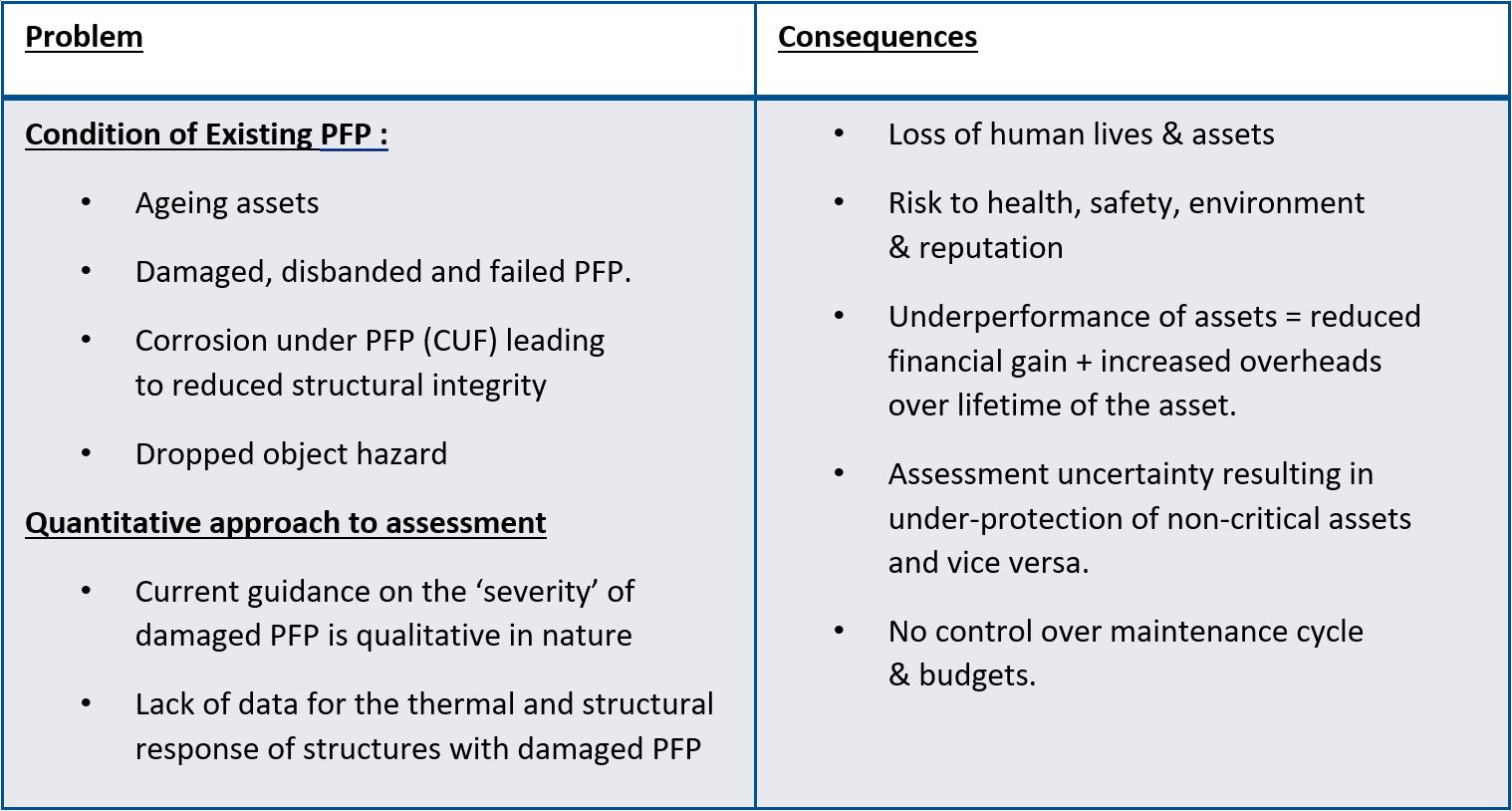

In most facilities across the world, there is growing concern on the aging passive fire protection (PFP) & its ability to protect steel structures in the event of a fire accident and provide the desired protection to people, assets and surrounding environment.

Like most materials, over time the PFP applied asset in service comes under varying levels of stress resulting in number of defects. These defects may develop within short time (days or initial months) and/or develop within long term (several months or years):

- Mechanical strain from operations

- Dropped objects

- Equipment vibrations

- Burn damages

- Water or solvent ingress over time

- Internal stress

- Wet freeze/thaw cycling and

- Defects due to continuous exposure to a hot climate/environment

Chartek 1709

- Developed for the on-shore market

- High temperature tolerance for process equipment & vessels

- 10 years proven performance in all environments

- Unrivaled track record in on-shore construction

- Over 2 million sq. m (20 million sq.ft) installed

Chartek 2218

- Innovative & patented technology

- Low certified UL1709 thickness for >90 mins

- Rapid cure down to minus 10ºC

- Faster return to service (less downtime)

- Reduces heating and localized climate control

- Extends maintenance window

- Reduced HSE risk – reduced access & man hours on site

Chartek 7E

- Chartek 7 technology (>25 years proven performance)

- Self reinforced- char stability based on a new patented additive technology

- Maximum efficiency >60 mins structural steel

- Up to 60 mins jet fire resistant to ISO22899-1

- Simplified application (less downtime)

- Reduced HSE risk – reduced access & manhours on site

Benarx Cast Solutions

- HSE Compliance- Fire protection for ‘Emergency Shutdown Valves’

- Minimal HSE risks involved in installation, in comparison to all surface preparation and wet coating application methods.

- Anytime access: re-inspection & maintenance

- Easy installation

- Not weather dependent

- No damage to adjacent equipment/ machinery (over-blast/ over-spray)

- No blasting contamination

- No/minimal downtime

Passive Fire Protection Resources

- PFP Infographic

- PFP Brochure

- Abstract (Establishing the need for a robust evaluation of damaged or failed PFP)

- Quiz 1

- Quiz 2

Performance Based Fire Protection Resources

Contact us

We are here to help

Our global team of technical and sales experts are available to provide you with the help and support that you need.

We have a team of experts in each industry, who understands your business and objectives.

Benefit from our continuous innovation and scientific expertise.

Our coating advisors all around the world assist you with your technical support and questions.